Polymer filter

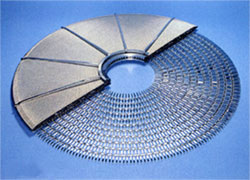

Leaf Disk Filters

Aupports high viscosity and large flow quantity

The leaf disk filter offers the large filtration area even in a limited capacity ,the high mechanical strength and the good rheological properties.Superior cleaning characteristics

Nagase provides not only a conventional wire mesh retainer supported leaf disk filter but also our original TP (Twisted Plate) retainer supported leaf disk filter, which can reduce the initial pressure drop, extend the on-stream life and achieve the easy cleaning, in a variety of sizes, hub designs, filtration efficiencies and types of porous metal filter media to meet every requirement.Product specification / filter size

| 4nch | 5nch | 7nch | 8nch | φ290mm | 12nch | |

|---|---|---|---|---|---|---|

| OD | 111mm | 149mm | 177mm | 222mm | 290mm | 304mm |

| ID A | 38.1mm | 38.1mm | 47.6mm | 47.6mm | 63.5mm | 63.5mm |

| B | 47.6mm | 47.6mm | 63.5mm | 63.5mm | 76.2mm | 76.2mm |

| C | 76.2mm | 85.2mm | 85.2mm | |||

| D | 115.5mm | 115.5mm |

Hub Designs

| TP soft hub | Semi-hard hub | TP semi-hard hub | Hard hub |

|---|---|---|---|

|

|

|

|

|

|

|

|

About TP retainer

The conventional type of leaf disk filter has a wire mesh retainer , which causes high pressure drop for the filter and this leads to problems as polymer stagnation , polymer degradation and gel creation.

The conventional type of leaf disk filter has a wire mesh retainer , which causes high pressure drop for the filter and this leads to problems as polymer stagnation , polymer degradation and gel creation.Characteristic of TP retainer

We show one example of the effect when I used TP retainer.

A low pressure loss / a longer life effect by TP retainer.

| A conventional type (Wire mesh retainer) |

A lower pressure drop type (TP retainer) |

|

|---|---|---|

|

|

|

| Pressure Drop | Wire mesh retainer has the structure that doesn't lead polymer to inner diameter. Therefore polymer stagnation could happen inside and the pressure drop is also higher. | The TP retainer has the structure that leads polymer to the inner side. Therefore it enables polymer to flow more smoothly from outside to inside and the pressure drop is lower. |

| Filtration | The effective filtration area is limited because outside area could not be used due to higher pressure of retainer. | The effective filtration area is bigger because polymer can easily penetrate into outside area of filter medium due to lower pressure of retainer. |

| Cleaning | It is tough to clean the space of backside of hub ring because it is too complicated structure. | It is more easy to clean even space of hub ring because it is very simple structure of hub design and has more open area in it |

Candle filter

There are two types of candle filter ; a tube type and a pleated type.

There are two types of candle filter ; a tube type and a pleated type.Characteristic

Pack filter

A pack filter is used for screen made of the stainless steel. We can offer various specifications of filter depending on applications and demands of customers.

A pack filter is used for screen made of the stainless steel. We can offer various specifications of filter depending on applications and demands of customers.

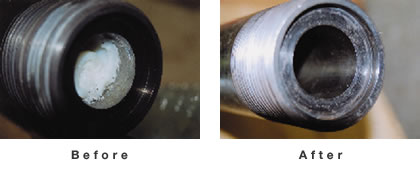

Filter cleaning service

Cleaning process

Inspection item

Available resin for cleaning

Premium cleaning service

Plumbing cleaning

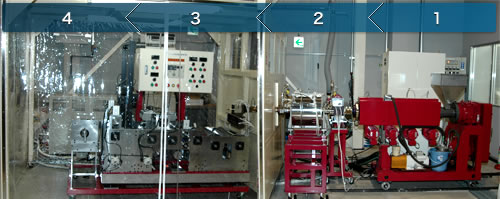

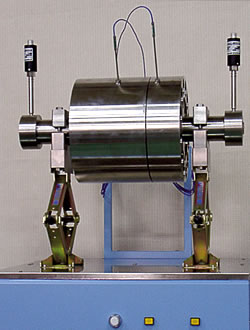

Test machine to evaluate Leaf disc filter(DENALYZER)

Facilities

(1)Monaxon extruder

(2)Leaf Disk Filters/DENAFILTER

(3-1)Clean room

(3-2)Rewind machine

(4)Detection machine/Web sensor

The comparison data of the quantity of alien substance by the difference of the filter.

【Condition】

【Measurement result.】

| The number of the alien substance counts. | |||

| S(50〜150μ) | M(150〜300μ) | L(300μ〜) | |

| Screen pack filter (#400 wire netting media). |

123 | 52 | 11 |

| A leaf disk filter (40 μ nonwoven fabric media). |

64 | 13 | 2 |

| A leaf disk filter (20 μ nonwoven fabric media). |

6 | 2 | 0 |

Filter rental airplane DENALAB

We can offer the test equipment for rental

Rental Contents

Rental Contents