Basic Approach

Prevention of Pollution

The NAGASE Group has established voluntary control values that are stricter than the standards set by the Air Pollution Control Act, Water Pollution Prevention Act, local ordinances and agreements, and is striving to adhere to them. We will work actively to reduce the release of pollutants and maintain and conserve the natural environment.

Resource Circulation

The NAGASE Group's environmental policy is to conserve resources, including energy and water, and to reduce and recycle waste. We will work toward a circular economy that aims to achieve both economic growth and a reduction in the environmental impact by reducing the amount of resources and energy input and the amount of waste generated and creating added value through recycling.

Targets and progress

Targets and Results for Resource Use and Waste Reduction

| Disclosure item | Target item | Boundary | Fisical year targets | Results for FY2024 |

|---|---|---|---|---|

| Raw materials | Amount of paper used | Non-consolidated (Tokyo Head Office) | Qualitative: In accordance with the NAGASE Group Environmental Policy (2. Promoting Environmentally Conscious Businesses), we will work to reduce paper consumption at offices. | Qualitative: Achievement Quantitative: Achievement 11.6% reduction (Year-on-year change) |

| Waste | General office waste Recycling rate | Non-consolidated (Tokyo Head Office) | Qualitative : In accordance with the NAGASE Group Environmental Policy (2. Promoting Environmentally Conscious Businesses), we will work to improve the recycling rate at offices. Quantitative : Recycling rate of 80% or more | Quantitative: 68.3% |

| Amount of general office waste | Non-consolidated (Tokyo Head Office) | Qualitative: In accordance with the NAGASE Group Environmental Policy (2. Promoting Environmentally Conscious Businesses), we will work to reduce the amount of waste generated at offices. | - |

For data on the amount of paper used, recycling rates, and amount of general office waste, please click here.

Support for the United Nations Food Systems Summit (FSS)

Nagase Viita Co., Ltd.

Nagase Viita Co., Ltd. has expressed its support for the United Nations Food Systems Summit (FSS), which is held to promote the transformation of the food system into a sustainable one and concrete actions toward the achievement of all sustainable development goals. Nagase Viita will contribute to the realization of a sustainable food system, especially food security covering both quality (nutrition) and quantity (supply), in order to enrich the health of all life and future food. Nagase Viita will promote the development of nutritious food products by utilizing the company's long-cultivated strengths in enzyme utilization technology and ingredients naturally derived from biotechnology. Nagase Viita will also work to secure stable food supplies by reducing food loss and improving the productivity of agricultural and livestock products.

Efforts for Recycling of Industrial Waste by Nagase Viita Co., Ltd.

Nagase Viita is actively involved in recycling the waste generated at each of its production sites. For example, metal waste from manufacturing equipment is provided to metal recycling companies, and wastewater sludge from wastewater purification facilities is provided as raw materials to companies that manufacture fertilizers and manure. As a result, the recycling rate of industrial waste at Nagase Viita Corporation has been approximately 98% at each production site.

3R activities in office buildings

In business facilities, it is very important to properly separate trash at the point of discharge. At Nagase’s Tokyo headquarters office, individual trash bins are not provided at work stations, but only at utilities located centrally on the floor, to promote 3R activities.

Targets and results for pollution

| Disclosure item | Target item | Boundary | Fisical year targets | Results for FY2024 |

|---|---|---|---|---|

| Contamination | New investment | Non-consolidated | Qualitative: In accordance with the NAGASE Group Environmental Policy (1. Compliance with environmental laws and regulations), we will strive to prevent pollution by controlling the emission of pollutants, and comply with environment-related laws, ordinances, and other laws and regulations in the promotion of our business activities. | Achievement |

| Production | Group | Qualitative: In accordance with the NAGASE Group Environmental Policy (2. Promoting Environmentally Conscious Businesses), we will strive to prevent pollution by controlling emissions of pollutants at production sites, and conduct production activities. | Achievement |

Please click here for VOC (air pollutant) emission data.

Pollution Prevention and Resource Recycling Initiatives

| Initiative | Details |

|---|---|

| Air pollution abatement through business process improvement and technology implementation | Provide and utilize exhaust gas treatment processesTo protect the atmospheric environment, emission standards have been established for soot and dust and VOCs, etc. The NAGASE Group provides wastewater and exhaust gas treatment technology solutions along its supply chain to meet these emission standards. In addition, the Group's manufacturing sites also install scrubbers to reduce emissions of hazardous gases and other pollutants.We also have our exhaust gas concentrations measured regularly by a third party. |

| Use of substitutes or less hazardous substances | Provide less hazardous alternativesIn order to prevent and minimize damage to the human body and the environment caused by handling chemical substances, it is necessary to obtain scientific information on the hazards and toxicity of chemical substances, assess their risks, and handle them appropriately. Since some of the amine curing agent raw materials provided by Nagase ChemteX Corp. are designated as deleterious substances, we provide "Denatite XNR3324/XNH3324" as a less hazardous alternative as a representative adhesive of non-poisonous substances. |

| Waste Management | Proper disposal of waste and reporting through electronic manifestsThe NAGASE Group has established a system for collecting and sorting waste to promote the reduction and recycling of waste from its factories and offices, and has set targets for these efforts in its environmental management system. In addition, in order to ensure that waste disposal responsibilities are fulfilled, on-site checks are periodically conducted on contracted waste disposal companies to confirm that waste is being disposed of properly.In accordance with the partial revision of the Waste Disposal and Public Cleansing Law (hereinafter referred to as "Waste Disposal and Public Cleansing Law") to strengthen measures against improper disposal of waste, businesses that generate 50 tons or more of specially controlled industrial waste will be required to use electronic manifests starting in FY2020, and we are implementing reporting We have been implementing electronic manifest reporting. |

Examples of initiatives

plaplat®:creating new value for business

The NAGASE Group recognizes that maintaining the convenience provided by plastics while taking the global environment into consideration is an important issue. Nagase & Co., Ltd. and Nagase Plastics Corporation operate an online platform called plaplat® that provides information on environmentally friendly materials such as recycled biomass and sustainable solutions such as CO2 visualization and energy-saving molding. It also provides a service that allows customers to request and receive a Certificate of Non-Use of Environmentally Hazardous Substances to confirm the safety of materials. It contributes to a sustainable society by creating new value for the plastics business.

Resin & Lab for 3D Printing to Support Resource Efficiency

The spread of 3D printers that do not require molds contributes to resource conservation in the manufacturing industry. The NAGASE Group recognizes that it is an important issue to support the challenge of its business partners through the provision of resin materials to manufacture products using 3D printers. Nagase ChemteX Corporation manufactures optical plastic for 3D printers. In addition, we have developed high-quality resins to match the curing characteristics of the 3D printer equipment and to meet various properties such as strength, heat resistance, rubber elasticity, and castability. At the same time, Open Lab supports manufacturing using 3D printers at suppliers.

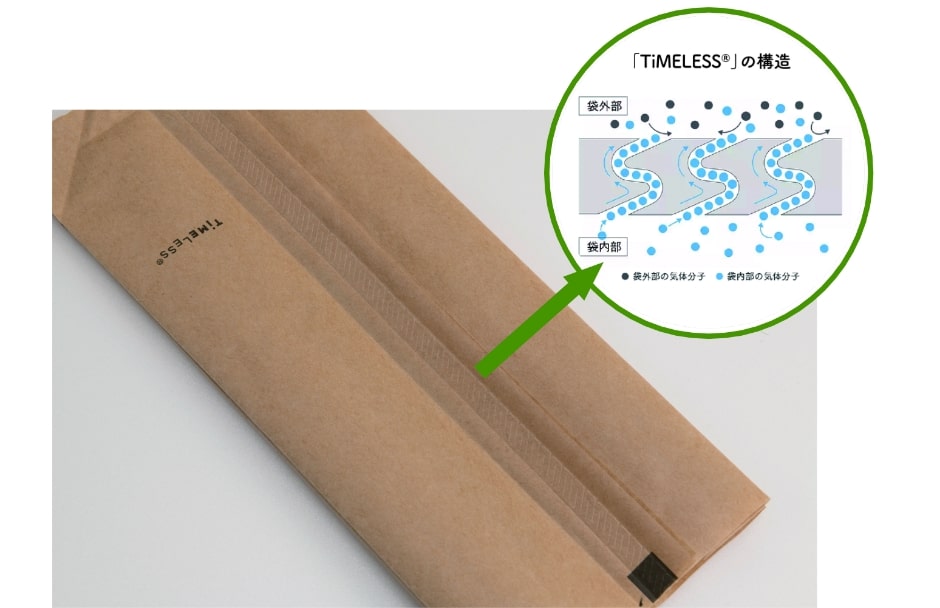

TiMELESS®:combining environmental friendliness with delicious food

The NAGASE Group recognizes the importance of providing packaging that preserves the taste of food products and is environmentally friendly. Nagase & Co., Ltd. is expanding sales of the gas control technology TiMELESS®developed by MIB Co., Ltd., which produces and sells packaging materials, etc. In May 2022, Nagase & Co., Ltd. developed asue, a barrier packaging material for food products that utilizes TiMELESS, with Nakabayashi Co., Ltd., Mitsubishi Chemical Holdings Group, Oji F-Tex Co., Ltd., and Kyokuyo Co., Ltd. In general, plastic valves are often used in the packaging of coffee beans to deaerate carbon dioxide emitted from the beans and prevent the bags from expanding and bursting. As an alternative to plastic valves, asue uses TiMELESS®, a technology developed by MIB that forms a flow path for deaeration, in the seal part. By doing so, the packaging material preserves the taste of food products and is environmentally friendly.

Since August 2023, it has been used for Sarutahiko Coffee Co., Ltd. coffee bean bags, and since July 2024, it has been used for POST COFFEE Co., Ltd. coffee bean bags.

Acquisition of ISCC PLUS certification

The NAGASE Group considers the promotion of biomass production related to climate change issues as an important challenge. NAGASE & CO., LTD. has obtained ISCC PLUS certification, one of the international certification systems for sustainable products. ISCC (International Sustainability and Carbon Certification) is already widely used in Europe as a certification system for biomass, and ISCC PLUS certification is a certification system that manages and secures products such as biomass raw materials and recycled raw materials produced by the mass balance method (*1) in the supply chain. ISCC PLUS certification for products from all over the world, including those from outside the EU, enables the handling of certified products. This year's renewal also allows for the handling of trimethylolpropane, pentaerythritol, and neopentylglycol. In the NAGASE Group, Nagase Wahlee Plastics Corp. (Taiwan) obtained ISCC PLUS certification. We will continue to contribute to the fight against global warming through the handling of ISCC PLUS certified products.

The NAGASE Group will comply with the latest ISCC regulations and manage its activities in accordance with the ISCC PLUS requirements.

- ※1A management and calculation method for products containing sustainable materials, such as those derived from biomass, and non-sustainable materials, such as those derived from petroleum. It is mainly used to promote biomass production in supply chains with complex production processes.

【NAGASE Group Companies with ISCC PLUS Certification】

NAGASE & CO., LTD.(Performance Chemicals Department, Polymer Global Account Department, Speciality Chemicals Department) / Nagase Plastics Co.,LTD. / Nagase (Thailand) Co.,Ltd. / Nagase Vietnam Co., Ltd. / Shanghai Hua Chang Trading Co.Ltd. / Nagase (Malaysia) Sdn. Bhd.

Building a sustainable food system through the use of TREHA®

The NAGASE Group considers the establishment of a sustainable food system as an important issue. TREHA® provided by Nagase Viita, a Group company, is making a significant contribution to improving food production volume and reducing food waste in the food production, processing, distribution, and consumption processes of the food system. The functions of TREHA® are as follows: in food production, as feed for livestock and fertilizer for crops, TREHA® contributes to the growth of agricultural products; in distribution, it contributes to the stabilization of the organization of vegetables and fruits, and maintains moisture and freshness for a longer time. We will continue to contribute to resource recycling by building a sustainable food system utilizing TREHA®.

Industry-Academia Collaboration Activities:

SIC Circular Materials Research Center

Nagase & Co., Ltd. has operated the “Circular Materials Consortium” together with Kyoto University Graduate School of Advanced Integrated Studies in Human Survivability (GSAIS) since September 2022, engaging in co-creation of knowledge toward the development of sustainable materials over a three-year period through October 2025. Through expert lectures and group discussions on topics such as the latest research trends in circular material design and environmental assessment methodologies, the consortium fostered cross-company learning and active exchange of ideas. As a result, it contributed to the formation of an industry–academia network and the creation of collaborative projects among participating companies. Building on these outcomes, the consortium will evolve from 2025 onward into the “SIC Circular Materials Research Center,” newly established within the Social Innovation Center (SIC) of GSAIS, Kyoto University, to further advance research, education, and industry–academia collaboration toward a circular society. Nagase & Co., Ltd. will continue to support the activities of this Research Center and contribute to the social implementation of circular materials and the realization of a sustainable society.