Basic Approach

The Sustainable Development Goals (SDGs) established and promoted by the United Nations include securing a stable supply of water and richer lifestyle, including access to water for all people.

Here, the NAGASE Group works to rigorously reduce, reuse, and recycle in its business activities, striving to improve its use efficiency and reduce its usage volumes.

Especially in areas with high water stress, we take measures according to the details of the risk by analysis using the Water Risk Filter (WRF).

Water Management Plan Status

Within the NAGASE Group, 10 companies have formulated water management plans, ascertained the volume of water taken and recycled, and are working to properly manage water resources and reduce environmental impact.

Water intake

All of our manufacturing sites draw water from third-party water supplies, and two of our production sites (Harima Plant of Nagase ChemteX Corporation and Okayama Functional Sugar Plant of Nagase Viita Co., Ltd.) also draw water from groundwater.

Water drainage

Okayama No. 1 Plant, Okayama No. 2 Plant, and Functional Sugar Plant of the Nagase Viita Co., Ltd. and Harima Plant of Nagase ChemteX Corporation discharge water into the river basin owing to the location of these plants. At the time of discharge, we promote various measures, such as reducing the pollution load to improve the water environment, and set management standards to maintain the quality of wastewater so that it conforms to environmental standards.

Recycling

Condensed water after steam generation is reused for boiler water supply at several sites. Nagase ChemteX Corporation uses recycled water for cooling in its water-cooled chillers.

Targets and progress

Targets and results for reduction in water resource consumption

| Disclosure item | Target item | Boundary | Fisical year targets | Results for FY2024 |

|---|---|---|---|---|

| Water resources | Volume of water taken and recycled Recycling | Group | Qualitative: In accordance with the NAGASE Group Environmental Policy (2. Promoting Environmentally Conscious Businesses), we will monitor the volume of water taken and recycled, manage water resources appropriately, and reduce the environmental impact. | Achievement |

Please click here for water resource data.

Efforts and performance to reduce water consumption

Nagase Viita Co., Ltd., Group

From September 2018 to the end of March 2020, a project was launched at the Imabo Plant of Nagase Viita Co., Ltd. to reduce water supply and drainage volume, and measures were implemented. By promoting the project, we achieved a 20% reduction (compared to FY2018 level) by FY2020.

In addition, Nagase Viita Co., Ltd. has established a sustainability action plan to reduce clean water consumption by 7% (compared to 2018 level / 1% per year) by 2025. The Manufacturing Coordination Committee shares in the efforts to reduce water consumption, and each Group company strives to do the same. The project utilized a water accounting system that specifically quantifies (quantifies) the costs and benefits of water usage reduction.

*90% coverage of sites targeted for reduction (FY2021, water intake)

Fukui Yamada Chemical Co., Ltd.

Fukui Yamada Chemical Co., Ltd. (Sakai-city, Fukui) is making use of the fact that it is located in an area with a high annual rainfall, and is making use of rainwater. Rainwater from the premises is stored in tanks (28 m3, 6 units) and used as dilution water at the wastewater treatment plant. As all the drains in the factory are connected to the catch basins, they are also used as a countermeasure against the risk of chemical leakage and other problems in the event of a disaster.

Water stressed area

The NAGASE Group conducted water risk assessments using the WWF Water Risk Filter every year.

We conduct risk planning for all disclosed sites (100%).

| Water risk assessment of our sites | Water risk management details | |||||

|---|---|---|---|---|---|---|

| Site | Water risk level | Water intake | Recycling | Water drainage | ||

| Third-party water supply | Groundwater | Release into rivers | ||||

| Nagase ChemteX Corporation | Harima Plant | 2.56 | 〇 | 〇 | 〇 | 〇 |

| Sakai Plant | 2.71 | 〇 | 〇 | |||

| Nagase Viita Co., Ltd. | Plant Ⅰ | 2.53 | 〇 | 〇 | 〇 | |

| Plant Ⅱ | 2.53 | 〇 | 〇 | 〇 | ||

| Functional Saccharide Plant | 2.53 | 〇 | 〇 | 〇 | 〇 | |

| Fujita Plant | 2.53 | 〇 | ||||

| Fujita Pharmaceutical Plant | 2.53 | 〇 | ||||

| Fukuchiyama Plant | 2.05 | 〇 | 〇 | |||

| NAGASE & CO., LTD. | Tokyo Head Office | 2.88 | 〇 | |||

| Osaka Head Office | 2.72 | 〇 | ||||

| Nagoya Branch Office | 2.77 | 〇 | ||||

| Nagase Bio-Innovation Center | 2.57 | 〇 | ||||

| Nagase Application Workshop | 2.57 | 〇 | ||||

| NAGASE Global HRD Center | 2.88 | 〇 | ||||

As of June 30, 2025

*The WWF Water Risk Filter is used to assess the water risk of our sites.

https://waterriskfilter.panda.org/

*Risk levels: Very low 1.0 - 1.8, Low 1.8 - 2.6, Medium 2.6 - 3.4, High 3.4 - 4.2, and Very high 4.2 - 5.0.

Engagement to conserve water quality at production sites

Nagase ChemteX Corporation

In 2025, the Harima Plant of Nagase ChemteX Corporation was assessed as a basin risk of 2.56 in the water risk assessment (basin risk) of its manufacturing sites using the WWF Water Risk Filter. In preparation for the tightening of regulations on water treatment standards, the Harima Plant has doubled the frequency of water quality tests currently required by law (once a year) and conducts them twice a year, measuring specific hazardous substances (dioxane) every month. Although we are not legally obliged to report dioxane, we are inspected once a year by the Nishi-Harima Prefectural Citizens Bureau of the Harima Prefectural Office, and we disclose the information at that time. Although we are not legally obligated to do so, we also report once a year to the Environment Division of Tatsuno City and the Ibogawa River Fisheries Cooperative Association.

Water and Wastewater Treatment

Collaborative Effluent Treatment System Utilization

Nagase Viita Co., Ltd. has introduced Aquablaster, a chemical-free wastewater treatment system provided by Aience Inc, a member company of the NAGASE Group, to stabilize wastewater treatment and reduce costs. Aquablaster contributes to solving wastewater treatment issues at food processing plants and hotels in Japan and overseas.

For more information about Aquablaster, please see the examples of initiatives below.

Largest ozone producing wastewater treatment plant in Japan

Nagase ChemteX Corporation, a member of the Nagase Group, purifies wastewater generated in the manufacturing process in its wastewater treatment facilities and discharges it into rivers with substandard water quality. In an effort to reduce its environmental impact, the company has continued to improve and upgrade its wastewater treatment methods and facilities. Waste water that could not be fully purified in the past

The water, which used to be treated as industrial waste, is now purified in an on-site wastewater treatment facility to reduce environmental impact through waste reduction. Furthermore, we have introduced an Advanced Oxidation Process (AOP) facility that utilizes ozone technology to prevent the discharge of wastewater that exceeds regulatory limits in the event of a COD level increase.

Recovery of Developer Used in Semiconductor Manufacturing

The NAGASE Group’s Nagase & Co., Ltd. and Nagase ChemteX which is involved in the semiconductor business, along with SACHEM, Inc. (President/CEO Rosemary Hoffman), will begin a project to collect and recycle the high-purity developer used in the manufacture of semiconductors (tetramethylammonium hydroxide: TMAH). The plan for this project is for SN Tech Corporation, a joint venture among the three companies involved in the recycling of developer, to introduce electrolysis and refinement technology in a new plant to be built in Higashiosaka. This will be the first example in the semiconductor field in Japan of collecting TMAH waste solution, recycling it, and reusing it as TMAH. There are also plans for SN Tech to manufacture and sell its Green Mobius System, which collects developer waste solution for use as a raw material, for semiconductor plants.

Water Risk Costs & Investments

As a chemical manufacturing company, NAGASE Group is required to have more stringent water treatment quality, and there is a risk that investment in wastewater facilities and other equipment and maintenance costs will increase. The amount of impact is assumed to be the amount of investment in water treatment facilities, and the amount of financial resources impacted by repair measures for wastewater treatment facilities is medium to high and has been identified as a significant risk.

Water and water audits

In order to increase the reliability of the information, we have obtained a third-party guarantee from Socotec Certification Japan K.K. regarding the water usage data we have on display.

Examples of initiatives

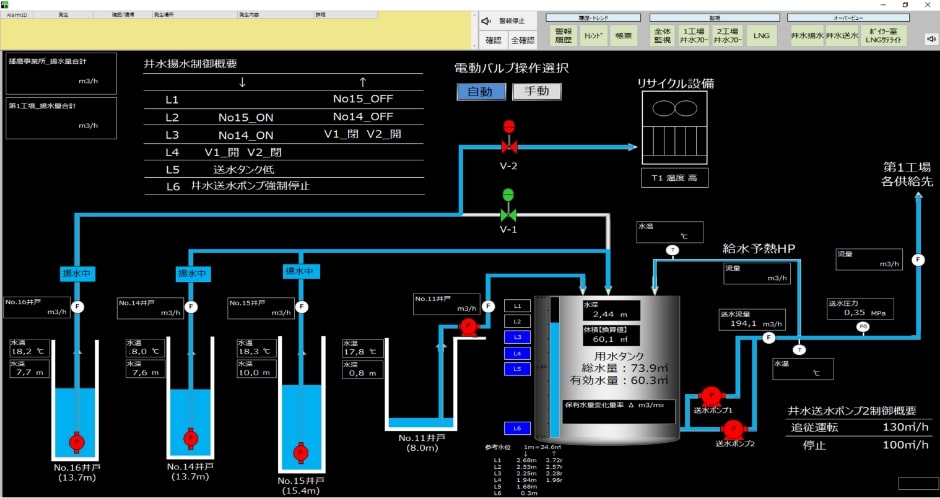

Utilization of well water

The NAGASE Group considers the 3Rs of water - reduce, reuse, and recycle - to be important issues in order to conserve limited water resources. The Harima Office of Nagase ChemteX Corporation is located in the Ibo River basin, where groundwater is abundant, and uses groundwater with a constant water temperature throughout the year as cooling water for the manufacturing process. We are also working on the 3Rs of water at manufacturing sites by cascading the use of cooling water as cleaning water in other processes.