NAGASE Group Supply Chain Management Policy

The NAGASE Group management philosophy is to contribute to society by maintaining the highest standards of integrity in our business activities. In order to apply this philosophy now and in the future and realize sustainable business growth, the NAGASE Group strives to fulfill our responsibilities across the supply chain.

All NAGASE Group executives and employees will make every effort to fulfill their responsibilities across the supply chain in compliance with this Supply Chain Management Policy (this “Policy”). Furthermore, the NAGASE Group will share this Policy with our business partners in the supply chain and engage in ongoing dialogues to ensure their understanding and compliance.

I. Supply Chain Management

1)Human rights and labor

The NAGASE Group is committed to respecting human rights in the course of our business activities and strives to avoid complicity in human rights violations through our business relationships, including in the supply chain.

- Prohibition of forced labor and child labor

We prohibit any form of forced labor and child labor and do not employ children younger than the minimum working age. - Prevention of unfairly low wages

In compliance with all applicable wage-related laws and regulations, we will strive to pay, at minimum, a living wage and will not make any unreasonable deductions from wages. - Elimination of discrimination and harassment

We do not discriminate on the basis of race, creed, sex, sexual orientation, gender identity, age, religious beliefs, nationality, language, physical characteristics, disability, financial assets, or place of origin. We will not engage in any form of harassment that negatively impacts the character or dignity of individuals, such as harassment based on sex, gender, maternity status, or seniority. - Respect for freedom of association

We will support freedom of association and the right to collective bargaining and will build positive labor-management relations. - Improving the working environment

We will create a safe and healthy working environment. - Contribution to local communities

We will protect the rights and livelihoods of local residents and contribute to the local community as a good corporate citizen.

2)Environmental conservation

By identifying the degree of environmental impact of our business activities, the NAGASE Group will work to reduce the burden on the environment and natural resources in our supply chain.

- Climate change

We will respond to climate change-related challenges by promoting measures to curb greenhouse gas emissions and reduce energy consumption. - Reduction of waste and circulation of resources

We will strive to protect the global environment by promoting waste reduction and reusing resources. - Management of hazardous substances and prevention of pollution

We will endeavor to prevent pollution by properly managing hazardous chemicals, waste, and other substances. - Water resources

We will strive to conserve water resources by promoting measures to improve water use efficiency. - Biodiversity

We recognize the importance of biodiversity and will strive to maintain natural ecosystems.

3)Ensuring quality and safety

The NAGASE Group will ensure the quality and safety of the products and services that we provide.

4)Thorough implementation of fair trade and anti-corruption measures

The NAGASE Group will comply with all applicable laws and regulations in each country and region in which we conduct business and will thoroughly ensure fair trade and implement anti-corruption measures.

5)Disclosure of information

The NAGASE Group will disclose information regarding this Policy in a timely and appropriate manner.

II. Monitoring

In order to assess the status of compliance with this Policy, the NAGASE Group will engage in dialogue with our business partners and conduct regular monitoring.

III. Response to Noncompliance

If a possible violation of this Policy is identified, we will promptly assess the situation at the NAGASE Group or the relevant business partner. In the event that a problem is identified that needs to be addressed by the NAGASE Group, we will make requests and offer support to the relevant business partner as needed to improve the situation. If no improvements are made, action will be taken without ruling out the possibility of reassessing the NAGASE Group’s transactions with the relevant business partner.

Method for selecting new business partners

The NAGASE Group asks new business partners to confirm the NAGASE Group Supply Chain Management Policy at the time of new transactions and to implement the following basic policy.

Audits of business partners

Group company Nagase Viita Co., Ltd. conducted an implementation audit (management system, transparency and business strategy, labor, health and safety, and environment) of a manufacturer of tapioca (base: Thailand), a raw material, in FY2023.

Security Trade Controls

Trade is the foundation of the NAGASE Group’s activities. To conduct appropriate trade in line with laws and regulations as a member of international society, the Security Trade Control Committee works to understand the export control situation, follow the latest revisions to the Foreign Exchange and Foreign Trade Control Law, and ascertain a detailed picture of export controls across the entire Group, while formulating related Group policies. The Item Compliance Management Council is in charge of directing and educating each business division and Group company in matters and statute updates determined by the Security Trade Control Committee. It is the responsibility of the Item Compliance Management Council to protect the Company and affiliates against the risk of illegal acts.

Specific Import-Export Management Framework

Information about our export products, technologies, and overseas customers is stored in and managed via our proprietary Product Management System. We confirm whether certain products or Technologies are subject to restriction under the rules of the Foreign Exchange and Foreign Trade Control Law and the U.S. Export Administration Regulations. Only those products approved by the Item Compliance Management Section are put into the system as products allowed for export. Going one step beyond mere adherence to the law, we define policies for the entire NAGASE Group associated with security trade controls that, as a rule, prohibit trade of products that are military-related items or that have military applications.

Efforts to Promote Personnel Development

The practical business of security trade controls changes every year. To keep pace with developments, the NAGASE Group encourages its employees—primarily those involved in export operations—to become Security Trade Control Associates by taking the exam offered by the Center for Information on Security Trade Controls (CISTEC).

| Qualified Security Trade Associates (Cumulative) | |

|---|---|

| Fiscal year ended March 31, 2018 | 890 |

| Fiscal year ended March 31, 2019 | 947 |

| Fiscal year ended March 31, 2020 | 982 |

| Fiscal year ended March 31, 2021 | 1,033 |

| Fiscal year ended March 31, 2022 | 1,089 |

| Fiscal year ended March 31, 2023 | 1,125 |

| Fiscal year ended March 31, 2024 | 1,166 |

| Fiscal year ended March 31, 2025 | 1,200 |

Membership in the RSPO (full membership)

In August 2017, NAGASE & CO., LTD. joined Roundtable on Sustainable Palm Oil (RSPO), which aims to procure palm oil that is environmentally sustainable, and is promoting the spread of sustainability throughout the supply chain by participating in meetings and briefing sessions. We have set a target to procure 100% sustainable palm oil by the end of FY2025.

Joining Sedex

In 2019, NAGASE joined Sedex, which promotes the creation of ethical supply chains.

Reaching out to the supply chain

Calculation and visualization of CO2 emissions in the supply chain using "Zeroboard“

“Zeroboard“ is a SaaS-type cloud service developed not only for the purpose of improving the efficiency of the company’s calculation of CO2 emissions, but also for the purpose of visualizing CO2 in the supply chain. NAGASE will contribute to the realization of a decarbonized society through the popularization of “Zeroboard“ mainly in the domestic and overseas chemical industries where NAGASE has a network.

For more information about “Zeroboard“, please see the examples of initiatives below.

Participation in supply chain initiatives

Each company of the NAGASE Group participates in the following supply chain initiatives and supports the relevant codes and guidance provided by each organization.

Other participating supply chain initiatives

KINKA CHEMICAL SOCIETY / Japan Chemical Exporters and Importers Association / Japan Chemical Industry Association / Center for Information on Security Trade Control / THE JAPAN PLASTICS INDUSTRY FEDERATION / Semiconductor Equipment Association of Japan / Association of PET TRAY / Japan Fashion Color Association / Japan BioPlastics Association / Japan Auto Parts Industries Association etc.

Supplier Policy on Animal Welfare

We request our suppliers to take the following actions regarding animal welfare.

When animals are used for testing and research, for the manufacture of biological products, or for other scientific purposes, to the extent that the purpose of the scientific use can be achieved, we will use alternative methods of providing animals as much as possible, reduce the number of animals used for such purposes as much as possible, and take other appropriate measures to ensure that animals are used appropriately. We will give due consideration to the use of the In addition, when animals are used for scientific.

Measures Against Conflict Minerals

A portion of minerals supplied by regions in conflict are said to be resources providing funds for inhumane armed forces, potentially leading to infringement of human rights.

The NAGASE Group, as a party building and maintaining responsible supply chains, conducts investigations as appropriate in the event of dealing in conflict minerals.

Conflict Minerals

Of minerals mined in countries and regions in and around conflict zones, this term refers to resources providing funding for armed forces. As defined in Section 1502 of the Dodd Frank Act, these are minerals such as tungsten, tantalum, tin, and gold that are produced in the Democratic Republic of Congo and proximate nations.

Examples of initiatives

VR content for experiencing workplace accidents in the chemical industry

In recent years, the increase in the number of workplace accidents and injuries in the supply chain has become a serious problem. In the chemical industry, which is our business domain, training methods that mainly involve classroom lectures and watching videos are common, but these methods have not been sufficiently effective for practical learning and raising awareness of the risks specific to the industry. The “VR content for experiencing workplace accidents in the chemical industry” was created and is being sold by Nagase & Co., Ltd ,JAPAN PAINT MANUFACTURERS ASSOCIATION, and TOPPAN Inc. in collaboration with the aim of reducing workplace accidents in the paint industry. Using VR goggles, this content allows users to experience three dangerous situations that are likely to be encountered in chemical manufacturing in a virtual space. Compared to classroom learning and watching videos, this VR-based training is expected to help workers better understand the dangers they may face in the workplace and enhance their awareness of the need to prevent workplace accidents. Training using this VR content will be provided to business partners and within the NAGASE Group. In the future, we aim to contribute to improving safety in the industry by expanding the content to address risks specific to the chemical industry.

The “VR content for experiencing workplace accidents in the chemical industry” is being sold by Nagase & Co., Ltd., a distributor of TOPPAN's “Safety Dojo VR®”, to the chemical industry. The goggles for the “Safety Dojo VR®” already have 10 types of general-purpose content developed by TOPPAN Inc. installed. The “VR content for experiencing workplace accidents in the chemical industry” being sold by Nagase & Co., Ltd. this time has been sold with three new types of content added for the chemical industry.

VR goggles

Sample image(Accidents caused by mixers)

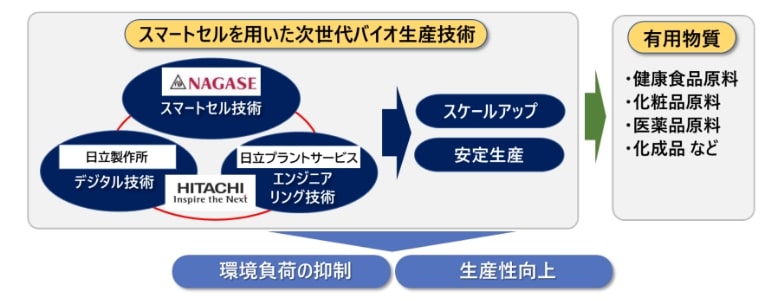

Started joint development for commercialization of production processes for rare amino acids using smart cells

The NAGASE Group believes that high-efficiency production of useful substances with complex structures, which were previously difficult to mass-produce, is an environmentally friendly development method from the viewpoint of reducing raw material consumption, waste, and energy consumption. In April 2022, Nagase & Co., Ltd., together with Hitachi, Ltd. and Hitachi Plant Services Co., Ltd., began joint development aimed at establishing a precision fermentation process for useful substances, including the rare amino acid ergothioneine (EGT), using microorganisms (smart cells) that maximize the production capacity of substances by combining biotechnology and digital technology. Specifically, the three companies, Nagase & Co., Ltd., Hitachi, Ltd., and Hitachi Plant Services Co., Ltd., will begin the following joint development activities aimed at commercializing production processes for useful substances such as EGT using smart cells by utilizing and integrating the experience and know-how accumulated over many years. The details of the joint development are as follows:

(1) Use of culture simulation technology and other methods to predict scale-up conditions for the smart cell culture process

(2) Analyses of data from lab experiments and production process studies to find process and scale-up conditions that maximize productivity

(3) Establishment of methods for engineering and optimizing production processes

Through the results of this joint development, we will work to solve issues toward EGT mass production processes using smart cells, and by applying these processes to various useful materials, we aim to realize a sustainable, healthy, and convenient society by both reducing environmental impact and increasing production efficiency.

Calculation and visualization of CO2 emissions in the supply chain using the Zeroboard

The NAGASE Group considers the calculation and visualization of CO2 emissions in the supply chain related to climate change issues as an important challenge. With the aim of supporting the decarbonization of corporate management, NAGASE & CO., LTD. has agreed to a business alliance for the sales and business development of Zeroboard, a cloud service for calculating and visualizing CO2 (carbon dioxide) emissions developed by Zeroboard Inc. and will market this service, ascertain customer needs, and develop and provide solutions for reducing CO2 emissions, mainly to the chemicals industry. As countries around the world strive to become carbon neutral by reducing CO2 emissions to zero as a whole, Zeroboard has been developed not only to improve the efficiency of calculating CO2 emissions for the company, but also to visualize CO2 emissions in the supply chain. From FY2022 onward, the two companies have been using the database to develop businesses such as a business-to-business matching platform to provide solutions for reducing CO2 emissions, and to propose efficient methods for calculating environmental data that capture changes in the external environment. Through this partnership, Zeroboard Inc. and NAGASE & CO., LTD. will contribute to the realization of a decarbonized society by supporting the decarbonization of corporate management.

Initiatives related to the environmental impact of the supply chain

Management of recycling operations and development of recycling materials

The NAGASE Group considers the operation and management of recycling in the supply chain and the development of recycled materials as important issues. NAGASE & CO., LTD., which holds the NAGASE Application Workshop, contributes to reducing the environmental impact through the operation and management of recycling in the supply chain and the development of recycled materials. We support the recycling of Tritan wine glasses (manufactured by Ishikawa Jyushi), which are used in all stores of Saizeriya's Italian restaurant Saizeriya, by providing recycled materials and developing products for Ishikawa Jyushi.